Despite decades of history and lessons learned, most organizations still haven’t figured out how to achieve ERP implementation success. In fact, our research over the years shows that most implementations still fail – despite lessons from history and advancements in technology. (For more on this, see our 2020 ERP and HCM Report).

Table of Contents

ToggleThe more things change, the more they stay the same

While technology has changed dramatically during my two decades in the industry, the ways that ERP implementations are managed haven’t changed that much. ERP vendors tout cloud ERP systems, agile implementation methodologies, and pre-configured solutions as examples of silver bullets that will ensure success, but these have proven to be false narratives. They also hype technology improvements like the internet of things, blockchain, machine learning, and artificial intelligence – all great advancements, but ones that do virtually nothing to enable success.

ERP implementation success shouldn’t be an elusive state of utopia that only a few chosen organizations can achieve. Achieving success is simpler than it seems, but it requires organizations to challenge the conventional wisdom perpetuated by ERP vendors and the big ERP systems integrators. In other words, it may require a different way of thinking, but it isn’t rocket science.

Below are ten initial steps toward your journey to ERP implementation success:

1. Define a clear ERP implementation vision and strategy

Defining and aligning on a clear strategy is one of the first steps to a successful ERP implementation. Most clients we work with embarking on a digital transformation or ERP implementation because they have to, either because their old system is being sunset and/or because they have outgrown its capabilities. These reasons are far from good enough.

Regardless of how urgently you do or don’t need to replace your current system, you need a clear vision and digital strategy to succeed. This vision needs to go well beyond “replace our current system” and get more into specific goals. For example, here are some more common and slightly more helpful goals:

- Standardize our operations

- Maximize flexibility in our sales processes

- Optimize inventory levels

- Enhance the customer experience

Even these high-level goals are just a start. Executive teams also need to further articulate what exactly these goals mean and how they relate to the ERP implementation. For example, what exactly do we want to standardize? What are our competitive strengths? What are the things we are less willing to simply accept the limitations of the ERP software? These questions are rarely thought through and articulated, yet they are an initial key to success.

This video provides additional explanation of how to get your executive team aligned on your ERP implementation:

2. Don’t spend too much time on selection

The ERP selection process has a tendency to result in biased vendor inputs and analysis paralysis. Vendors typically say “yes” to questions about software capabilities, regardless of how well those needs are met. Unqualified ERP consultants and internal project teams provide incomplete and biased analyses that make for a difficult decision.

Since most organizations have limited time and resources, each dollar and hour invested in the selection process is less time and money being invested in critical implementation activities. This is why it is important to get to a software decision as effectively and efficiently as possible. Leading independent ERP consultants such as our team at the Third Stage is one example of how you can mitigate these blind spots.

3. A strong implementation is better than a perfect ERP software selection

Building on the previous point, most organizations are better off investing more heavily in an effective ERP implementation rather than burning time and money in the quest for the perfect ERP software. Analyzing too many options for too long has a point of diminishing returns, which most teams and consultants blow right past.

During our client work, we typically find that most organizations realistically have three or five viable options to choose from based on their unique differentiators. The sooner you can get to this short-list, then the less wasted time you will spend analyzing systems that were never going to be a good fit for you in the first place. Once you have narrowed your ERP short-list, you don’t want to flip a coin to make your decision, but you also don’t want to spend months analyzing systems that will all probably work pretty well for your organization.

4. Recognize that there are no silver bullets

We are all human. We hear what we want to hear. When we hear that some new, revolutionary technology or toolset is the key to solving ERP implementation problems of years past, it is natural for us to listen carefully and start drinking the Kool-Aid.

But it’s also important that we don’t fall for it. There are no silver bullets or easy answers to success. Whether it’s industry templates, agile implementation methodologies, or sexy new technologies, these will not make for easy implementation. Instead, the key is to focus on the non-technology aspects of your implementation, which are covered in the remaining steps here.

This video unpacks some of the myths and hoaxes commonly perpetuated by ERP vendors and systems integrators:

5. Begin with realistic ERP implementation expectations

During our ERP expert witness work analyzing ERP failures and lawsuits, we find that unrealistic expectations are the first of a series of chain reactions that lead to failure. When a team expects implementation to be completed with too little time, money, and resources, it inevitably leads to bad decisions later on.

For example, one of my first expert witness engagements involved a large company with over 30 locations that tried to implement SAP. Leaning on out-of-the box software, industry accelerators, and a “no-customization” approach, the vendor and systems integrator told them that the entire implementation could be completed in 36 months. This estimate turned out to be wildly inaccurate.

As the project continued, the team quickly realized that they were struggling to even get a single pilot location up and running in that amount of time. As a result, they cut back on organizational change management, business process scope, and other activities that would have been the key to their success. This entire sequence of events culminated in a high-profile lawsuit later on.

So, what is the lesson here? Take your ERP vendor or system integrator’s proposed implementation plan with a grain of salt. Identify the areas that they have underestimated or excluded completely. And most importantly, get an unbiased assessment of your plan before you commit to it.

6. Treat your ERP implementation as a business transformation – not technology project

As cool as technology is, it has a way of needlessly complicating things. Time and time again, we see organizations get stuck in the mud trying to untangle complex technology issues such as customization, integration, and tying it all together. This stuff is largely irrelevant in the grand scheme of things.

Rather than overcomplicating and overinvesting in the technical side of your implementation, we challenge our clients to move more time, money and focus to the non-technical aspects of ERP implementations. Things like a clear strategy, organizational change management, effective business process management, and other things covered in this list are going to be much more important to your odds of success.

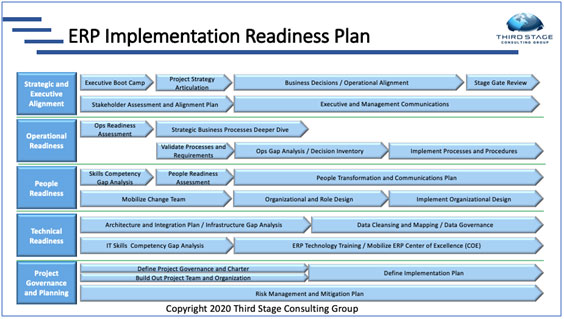

7. Prepare well for implementation

Before jumping headfirst into your implementation, it is important to get your house in order. Just like when building a new house, you wouldn’t expect the general contractor, electricians, plumbers, and roofers to show up without first defining a detailed blueprint for what the transformation is going to look like.

Similarly, you don’t want your army of systems integrator consultants to show up, start the meter on their billing, and just start building and testing stuff without clear direction. This is a very expensive and inefficient way to manage your implementation. Worse yet, it results in the unintended consequence of your systems integrator owning and taking over your implementation rather than your internal team.

Below is a visual of some of the workstreams we recommend addressing during the pre-implementation readiness phase of your project:

8. Leverage the right ERP implementation project team

You want the A-team on your ERP implementation project team. When it comes to your internal team, these are the people that are the most difficult to pull from their day jobs. They are people that typically understand current operations well, but also have a vision for how things could be improved in the future.

When it comes to external project team members, you want to first and foremost be selective about where you use them. It is common to understand the need for functional and technical experts in the software you have chosen, but other roles are even more important. For example, organizational change management, business process reengineering, and strategic alignment are just a few of the roles that are critical, yet not addressed by most systems integrators.

This video outlines some of the key project roles that you should focus on during your ERP implementation:

9. Invest heavily in organizational change management

I have yet to meet the CIO that said, “I really wish we would have spent less time on our change management efforts.” I don’t know that this person exists. But I have heard countless executives and project team members that after the fact wish they would have spent more time on their change management efforts. This is true even for our clients that hire us as their organizational change management consultants.

Whatever amount you are planning to spend on change management now is probably not enough. Even if you think your team is excited for the change (which they probably are), change management will absolutely become a critical issue at some point along the way. Don’t get too complacent in the meantime. It may require diverting time and resources from other activities, but doing so is a very smart investment.

10. Implement an independent ERP implementation quality assurance and risk mitigation framework

The last thing you want is for your vendor or systems integrator to self-assess how great of a job they are doing. They have a lot to lose if they share too much insight into the project risks or challenges that they might be running into. In other words, you don’t want the fox guarding the henhouse.

But organizations need full transparency and an honest assessment of what is going well and what needs to improve. If your project team waits until it feels the pain of those risks, it’s typically too late to fix. This is where an independent third-party – with nothing to lose by identifying and mitigating risk – can be extremely beneficial.

This video explains how quality assurance frameworks can be used to mitigate risk on your ERP implementation:

Key takeaways

Hopefully, you agree that these implementation best practices are not that difficult. It requires discipline and focus, but there is no magical or secret formula for success. These are just a few of the simple fixes that will make your implementation more successful.

To read more about this, download our “20 Lessons from 1,000 ERP Implementations” digital book, which contains more detail about the lessons covered in this article, along with 10 other keys to success that aren’t listed here.

I hope this helps. Please feel free to contact me to brainstorm ideas to make your ERP implementation more successful. I am happy to be a sounding board as you continue your transformation journey!